In 2016, Shanghai Quanray cooperated with COMAC to provide tools and intelligent management tools for automatic drilling and riveting platform of C919 aircraft. Of sharp air tools management scheme, through the resistance to metal tools for the toolkit pasted on RFID tags, air tool identification, recognition and counting, and the tool with the software system with rough positioning, is toolbox has IntelliSense, intelligent identification, automatic abnormal records, statistics, analysis, smart early warning, and other functions.

Quanray "RFID aviation intelligent Toolbox" system includes computer software applications and mobile applications, mainly to achieve the relevant data, information, view and management. To achieve the standardization of tools, intelligent use, The aviation smart toolbox has the following main functions:

Ø tool to prevent and reduce loss and theft

Ø simplify the registration process of tools and outbound.

Ø avoid errors due to manual management, to avoid missing or inventory management oversight.

Ø by cutting tool replacement cost, time cost and efficiency of management and achieve the appropriate return on investment.

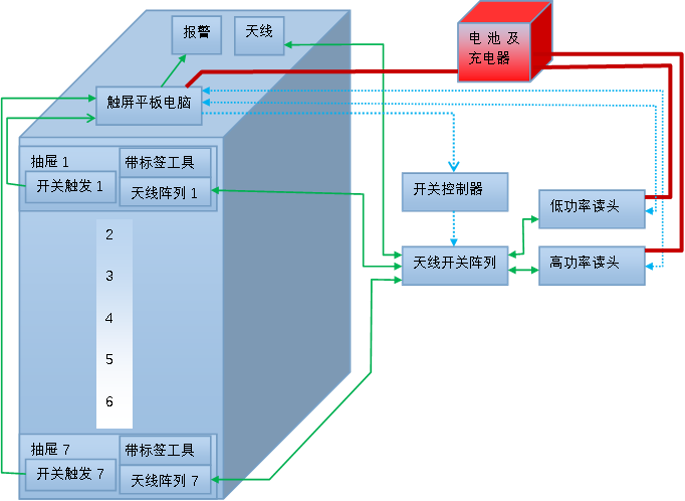

The following is the architecture of the intelligent toolbox system.

After using the aviation management tools of Quanray Electronics, COMAC has greatly reduced the staff's workload, and the accuracy of the tools has been greatly improved. The person in charge of this project of COMAC said, "Kunrui Electronics is targeting the flat tail of our C919 aircraft. The customized intelligent management tools of the automated drilling and riveting platform and the drilling template's intelligent management tools have helped us improve the level of tool management. In the future, the two parties will have more opportunities.

点击咨询

点击咨询 021-68795432

021-68795432

沪公网安备 31011502003477号

沪公网安备 31011502003477号