Quanray Electronics is a Shanghai Dairy Co., Ltd.-Jinshan Dairy Farm, piloting an RFID traceability management system. Quanray makes full use of RFID and big data technology to establish a full range of information traceability systems for pastures, to improve the quality control efficiency and information level of Guangming Jinshan Breeding Dairy Farm, and provide dairy safety information traceability services.

First of all, Quanray Electronics helped Bright Jinshan Dairy Farm improve the ranch management system, upgrade the automated ranch traceability management equipment, and realize daily management support such as dairy cow breeding, dairy breeding, on-site environment, feed feeding, milking information collection, raw milk inspection, indicator warning, etc. And traceability information management.

Next, the milk source traceability information management system is constructed. Before raw milk transportation, RFID tags are affixed to the milk cylinders, milk trucks and milk cans, so as to carry out data transmission at the pasture end during the milk receiving process and realize data traceability from the farm to the factory.

Main information transformation nodes:

1. On-site: Data collection, query and analysis support are completed at the first site to maximize efficiency.

2. Integration: open multiple systems at the data/interface level for compatibility processing and data closed-loop formation.

3. Electronic ear tags: Electronic ear tags used by cows are compatible with UHF and LOW-frequency. Remote data collection can be achieved through the UHF chip, and a low-frequency chip can be read by the milking table to realize the statistics of the individual milk quantity of cows.

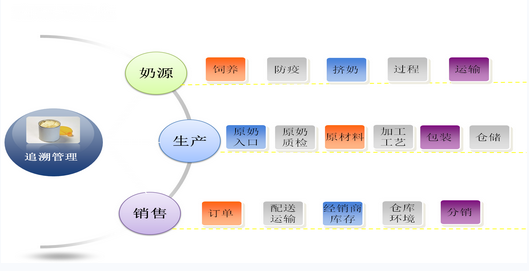

4. The pasture traceability management system comprehensively manages the various businesses of the pasture, which mainly includes: group pasture management system, feed supply chain inventory management sub-module, TMR feeding execution sub-module, input management sub-module, traceability analysis decision platform, equipment management sub-module Module, personnel management sub-module, etc.

UHF/LF RFID ear tags

The new version of Quanray high and Low-frequency electronic ear tag has an anti-change function. If the ear tag is cut off, the ear tag will be replaced. If the handwritten ear tag's internal code is not recorded in the system, the ear tag will be replaced without permission. The 900MHz UHF RFID chip is embedded in the ear tag, which can achieve a reading distance of up to 10 meters, supporting various innovative Internet of things applications in the dairy farming field. 134.2khZ low frequency is enclosed in the circular shape of the ear brand common mark, which can be seamlessly connected with the milking table.

Calf growth indicator was measured.

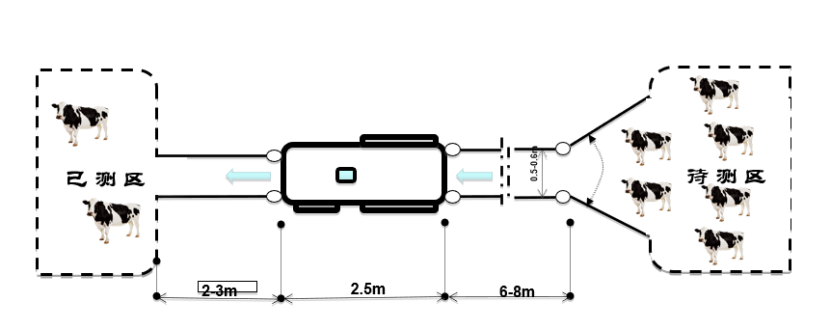

When cattle pass through the gate passage, they are weighed dynamically and the electronic ear tags are identified. The weight data is automatically summarized and displayed in the electronic ear tag identified by the software and uploaded to the database. Replace the old cattle weighing board record data input mode. Low-frequency electronic identification is implanted subcutaneously in newborn calves to control calf loss and prevent illegal operation. Cooperating with the elimination of the Niuniu certification system can guarantee the production safety of Guangming Group.

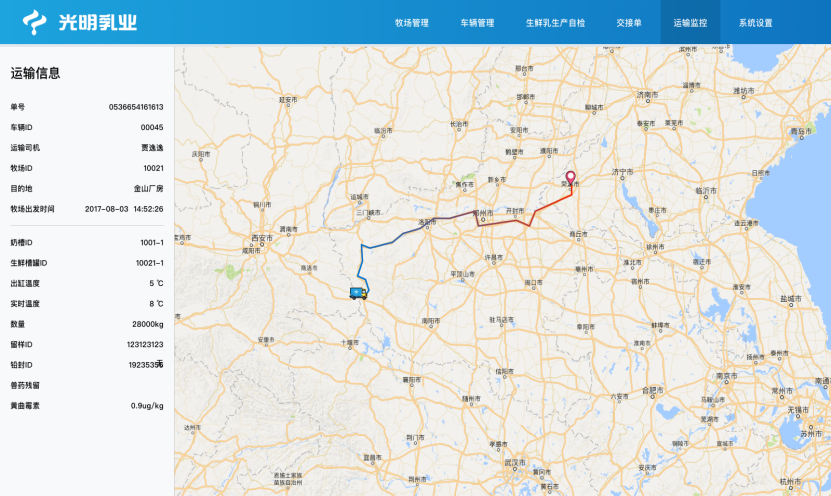

Combined with the actual situation of dairy production, the system realizes the collection of milk source information and vehicle information based on RFID technology and wireless communication technology, and identity identification based on ID information collection. The whole life cycle of milk products for information for early warning, alarm.

Through vehicle RFID tags, Transport personnel RFID work CARDS, RFID lead seals, etc., each vehicle's raw milk transport data is related to form the whole process data collection and control from dairy milk cans to factory milk cans. Integrate existing transport vehicle GPS system, associate transport documents, archive and conduct subsequent big data analysis, and realize an integrated collection of quality control data.

点击咨询

点击咨询 021-68795432

021-68795432

沪公网安备 31011502003477号

沪公网安备 31011502003477号