By the end of 2019, China's railway mileage will reach more than 139,000 kilometers, including 35,000 kilometers of high-speed rail, ranking first in the world. China HSR is designed to operate passenger dedicated lines with a speed of more than 250 km/h (including reservations) and initial operation speed of more than 200 km/h. From 2010 to 2018, China has built high-density high-speed rail networks in urban agglomerations in the Yangtze River Delta, Pearl River Delta, Bohai Rim and other regions, and completed high-speed rail connectivity between the eastern, central, western and northeastern areas. It has dramatically improved the comfort and efficiency of people's travel.

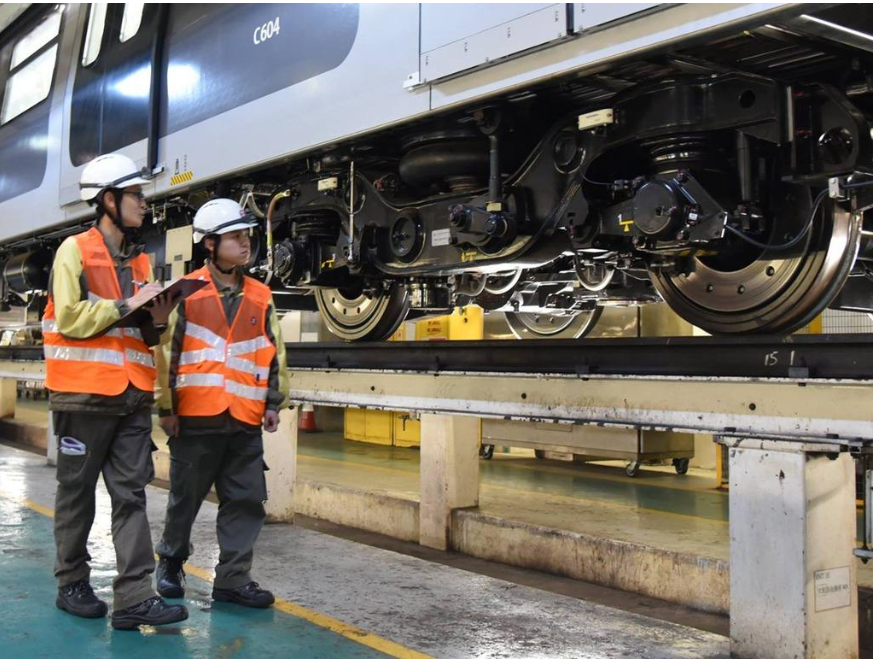

The wheel is a crucial part of ensuring high-speed trains running at speeds above 250 kilometers per hour. As a wheel with severe daily wear, its single operating life is half a year, and the wheel is divided into five levels of repair. Bullet trains and high-speed rail locomotives need maintenance when they run for 4,000 kilometers or 48 hours. According to the speed and mileage of high-speed rail, they need maintenance almost every day.

When the length of high-speed trains reaches 30,000km, the trains need to be put off the line and put in storage for repair, which requires secondary maintenance every 10 days. For each change of worn splint, the camera should be used to record it, and the recovered splint should be processed, and the image data should be left for each operation. Maintenance personnel usually carry a small notebook to record in detail the types of replacement parts, maintenance content, maintenance time, and maintenance personnel.

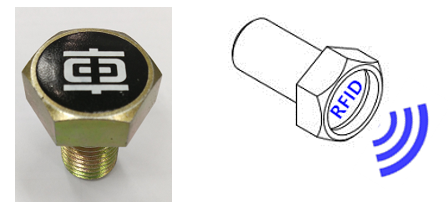

Through the cooperation with the strategic system integrator of high-speed rail, Shanghai Quanray provides the relevant railway departments with a safe, reliable, stable and intelligent one-stop solution for high-speed rail bullet train wheels. The RFID tag of high-speed railway adopts the latest QSTAR-56 USER area 2Kbits chip, which ensures the fast reading and writing of a large amount of offline information. Simultaneously, due to the huge centrifugal force generated during the locomotive operation, the unique mechanical design structure of the bolts ensures the safety and stability of the label mounting without affecting the body's strength.

The staff carries out regular maintenance. A large amount of information on each maintenance is stored in the TAG QTAG-5601, which is communicated with the reader through rf technology and accessed to the storage cloud background database. The unit wheel maintenance time has been reduced from 8-10 minutes to 2 minutes. It dramatically reduces the working pressure of patrol inspectors and improves the accuracy and efficiency of maintenance work.

点击咨询

点击咨询 021-68795432

021-68795432

沪公网安备 31011502003477号

沪公网安备 31011502003477号